Rigid

sHEET EXTrusioN aND CoEXTrusioN liNE

sMARTFLAT

The extrusion and coextrusion line for rigid plastics are designed to process materials such as LDPE, LLDPE, hDPE, PP, hIPs, ABs, PvC, PET and acrylic.

The extruders has unique screws designs, applied in each situation of the material.

screen changer filter drawer type (hydraulic or pneumatic) developed for quick and continuous changes.

FlaT DiEs

The flat die is designed according to the processed material, the width and thickness of the sheet, prepared for the use of feed block, for use in multilayers coextruders, making a perfect distribution of the materials. It contains gear pump that controls the pressure of mass before and after it, accelerating the speed of the extruder, maintaining the volume and constant die pressure automatically.

laMiNaTiNg CalENDEr

The calender is composed by three rolls with bimetallic surface, treatment with hard chrome and mirror polishing. The closure of the rolls is done mechanically with linear guides. The calender can be manufactured in several configurations according to the processed product.

WiNDErs

The winding system can be made by hydraulic shafts, for reels type “jumbo” or expandable shafts controlled by A.C. motors and frequency inverters, allowing greater precision in winding. Besides the winding system, it has the option of cutting with guillotine the necessary measures for stacking sheets.

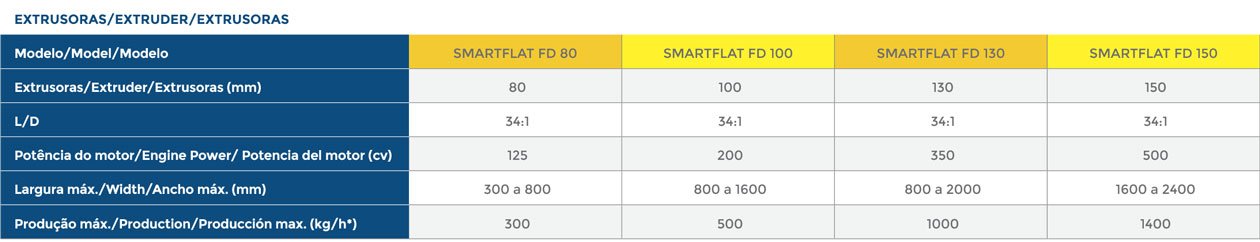

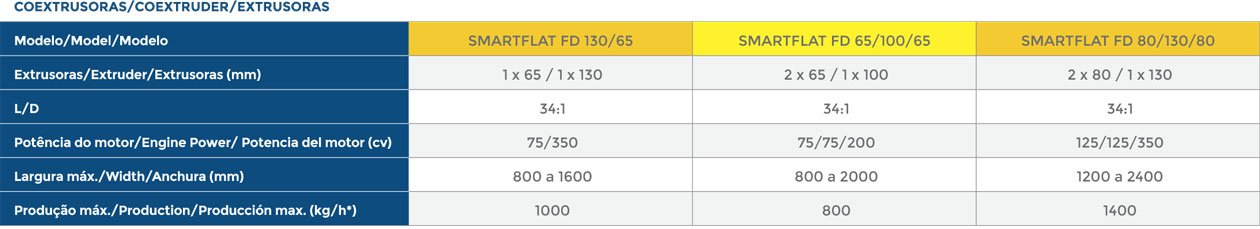

The maximum production of the extrusion depends on the material, width and thickness of the sheet.

The maximum production of the extrusion depends on the material, width and thickness of the sheet.